Putsch® offers a myriad of solutions for cutting and grooving on solid surface, aluminum composite materials, high-pressure laminates, plastics and sandwich panels. We offer a variety of kits that will adapt any of our vertical panel saws to properly process your chosen material, as well as special edition versions of our SVP 420 Series.

Motorized scoring for laminates and fine woods

Putsch® offers independent motorized scoring that is standard on our SVP 320/420 Series and SVP 980 A/T vertical panel saws. For saws that do not feature active scoring, we offer a scoring knife attachment that scores material before the blade to help ensure clean cuts.

Solid surface cutting

Corian, Formica or other solid surface materials have different cutting requirements than other materials. By installing our Solid Surface kit, we can configure any SVP vertical panel saw to cut these heavier materials while offering a seamless edge. The kit also includes an adjustable depth stop.

Thin laminates and veneers

Thin materials such as veneer or laminate require more support behind the material to prevent flexing during cutting. Putsch® can offer this additional support with a grooved MDF grid surface.

Panel saws to process the materials you need

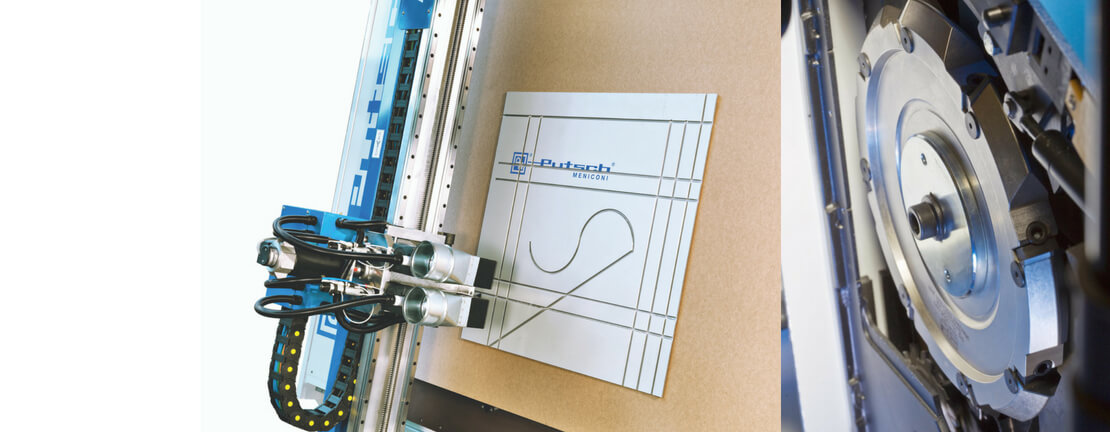

The time-saving Putsch® SVP 420 ALU features a dual-tool saw head that contains both a 200 mm saw blade and 100 mm cutter, so an operator can move between cutting and grooving operations without downtime due to removing blades.

The Putsch® Alucenter Vertical CNC Workcenter couples cutting edge technology with space-saving design. Capable of true X-Y-Z axis movement, the Alucenter can process ACM and HPL panels with ease. The work area has five vacuum zones to hold parts securely against a sacrificial MDF surface.

90° Grooving,

V-Profile

Creates a right angle (90°) fold.

135° Grooving,

V-profile

Fold two 45° panel to complete a 90° corner.

Rectangular Grooving,

U-profile

for folding to 150°, according to the panel

SVP 145 V-GROOVING

Vertical panel saw suitable for cutting and v-grooving operations on composite materials