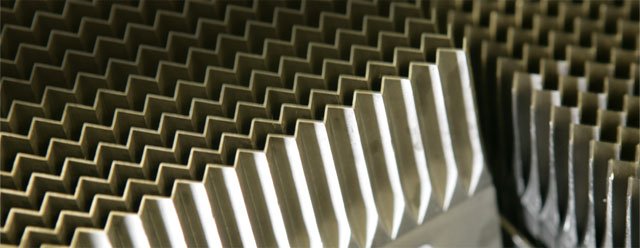

A profitable sugar production process is not possible without a good cossette. It is critical to have the best beet knife in the world to maintain positive impacts downstream. Putsch® beet knives, in connection with a well-maintained slicing station, ensure the highest quality cossettes: the excellent surface area per volume ratio optimizes your sugar extraction.

Over the past 150 years, Putsch® has perfected the beet slicer knife. Special-made steel and unique properties give our beet knives an edge over the competition. We have achieved the ideal combination of ductility and hardness in our knives; they do not rip or bend easily. If they do bend, Putsch® beet cutters work well with geared straightening rollers (one of many Putsch® patented innovations), even when others don't.

Putsch® supplies knives in a variety of models, divisions and lengths for all commonly used beet slicing systems:

- Putsch® TSM Drum Slicers®

- Ogden Slicers

- Disc Slicers

Advantages:

- Engineered to meet harsh conditions in North America

- Produced in the USA

- Strong, robust and sturdy

- Great resistance against bending down

- Packaging has color-coded labels for A or B knives, and is 100% recycled material

- Flexible delivery for special requests

- Still manufactures knives for Ogden slicers

- Quality control and consistency through continued testing in our laboratory

As the market leader, Putsch® knows where the metal hits the beet. For more information or to order, please contact Customer Service.