Putsch® has designed its cane sugar processing systems and equipment to tackle the stickiest issues in your process. Our approach, however, is not one-size-fits-all. Two qualities Putsch® systems have in common are top-to-bottom efficiency and the most economical configurations possible.

Through more than 150 years of sugar experience, Putsch® has modernized traditional melt clarification processes. We offer improved direct processing Carbonation systems.

Putsch® can help with customized studies, pilot tests, process optimization, planning, engineering, delivery, installation, automation/programming, start-up services, staff instruction/training and updates. We can easily optimize and adapt our products to your existing refinery.

- Carbonation systems with Richter tubes

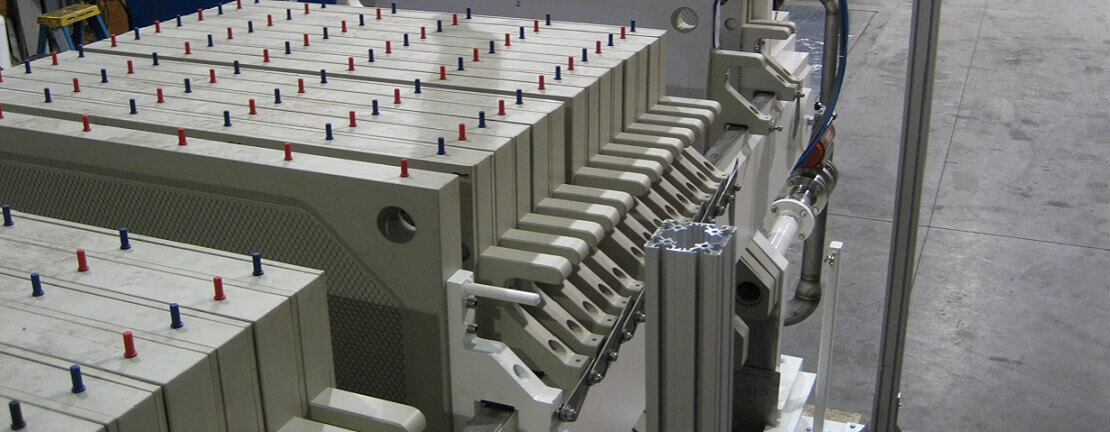

- Membrane filter presses

- Sibomat: automatic screen filters

- Candle filters

- Centrifugal screens

- Sugar elevators

- Sugar bulk-loading systems

- Automation / DCS systems

- Filtration-coefficient measuring instruments

For more information check out our brochure on cane sugar technology.

Advantages:

- More efficient and economical system

- Robust and reliable

- Low total cost of ownership

- Adaptable to almost any condition

- Designed solely for cane sugar refineries

- Integrated approach to product engineering and service

- Industry leading smart automation in connection with Putsch® DCS Systems

For more information on operating schematics and technical data, go to our Downloads page.