Depending on the model series, the EBP Series Edgebanders can be outfitted with the following production enhancing features and accessories. Consult your Putsch® representative or authorized Putsch® dealer for which option(s) are best suited for your needs.

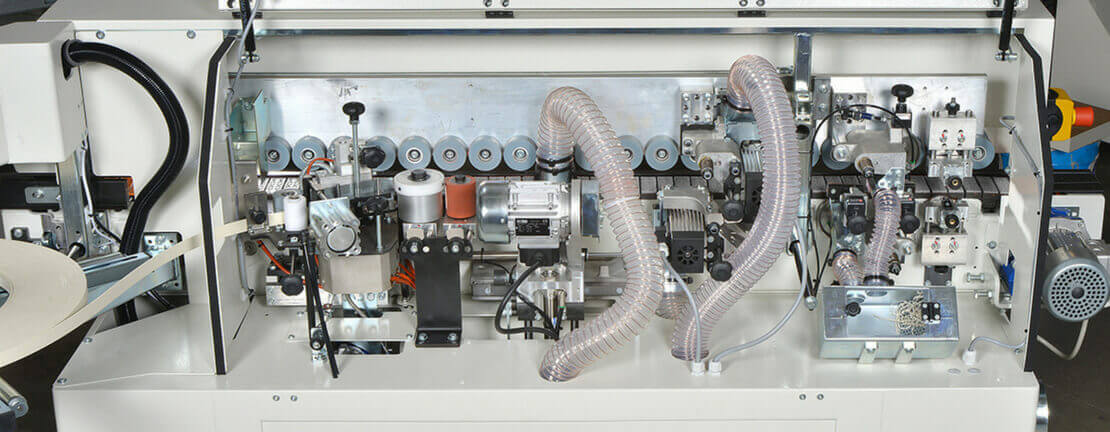

PURE Glue System

The gluing unit processes PUR or EVA glue. With PUR glue, it is possible to stop the machine for up to four days with no cleaning required. Thermal regulation with automatic standby allows for two different temperatures to be set. Updated system that will begin production in September 2018 includes automatic glue drainage cycle, and the possibility to save personalized glue quantities.

VR End Trim Unit

Available on the EBP 420 and 950 Series, the VR End Trim unit adds radius vertical end trim (along with straight) to create a "corner rounding" effect to the leading and rear edges of the panel. This unit is substituted for the standard end trim unit, and includes an integrated dust extraction system. The VR End Trim unit will be in production starting October 2018. Not available with the 950 CR and 950 PMCR.

Infrared Lamp

Infrared lamp pre-heats the edge of the panel after pre-milling prior to glue application in order to improve adhesion. The infrared lamp is recommended for cold climates and for facilities storing panels in cold conditions.

Edge Scraping Unit

Eliminates notches left by flush trimming unit for perfect edge finishing. The edge scraping unit comes with a vertical disc copier and front copy pad to adjust the operating tool position, and a dust extraction box to collect shavings. 2 mm cutters are standard, with 1 mm and 3 mm available upon request.

Glue Scraping Unit

Top and bottom scraping knife unit designed to remove the excess glue joint from the panel surface.

Buffing Unit

The buffing unit is fitted with two independent motors (0.13 kW at 1,400 RPM) for perfect finishings of ABS and PVC edges.

Cleaning Spray Agent Unit (only with buffing unit)

The cleaning spray agent unit improves panel cleanliness and edge polishing when combined with the buffing unit. The unit includes two sprayers (upper and lower) and a liquid tank. The spray function is controlled by the PLC.

Anti-adherence Release Agent Spraying Unit (only with pre-milling unit)

This release agent spraying unit prevents any excess glue from adhering to the upper and lower panel surfaces, and also facilitates and improves cleaning in the gluing line area. The spray function is controlled by the PLC.

Antistatic and Cooling Spray Unit

The unit speeds up cooling and hardening of the glue, and facilitates removal of glue residues. It also eliminates the electrostatic charge of the plastic shavings, reducing obstruction of the tubes and increasing dust extraction efficiency. Electronically controlled, the unit uses two nozzles and a liquid tank. Highly suggested when the PURE glue system is in use.