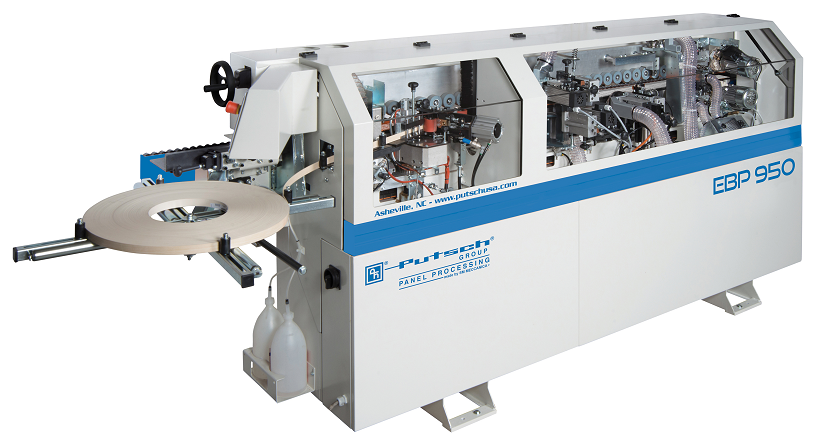

The EBP 950 is our most flexible edgebander that includes three spaces for optional edge scraping, glue scraping and buffing operation along with anti-adhesive and cleaning spray stations. Moving at a speed of 9 meters per minute, the chain feed system has scratch-resistant rubber pads to carry the panel for consistent banding. The easy-to-adjust top bar includes a double row of rubber rollers to secure the panel.

The EBP 950 handles banding from .04 to 3 mm thick and panels up to 50 mm in height (45 mm if using corner rounding unit). Coils are cut using an oscillatory cutting shear for uninterrupted edge feed. The machine has an automatic single-motor end trim unit with two 80 mm blades. The flush trim unit has 75 mm cutters (with disposable knives) that offer a straight / 2 mm radius / 15° bevel. The flush trim unit also includes 120 mm scratch-resistant vertical disc copiers that are ideal for delicate finishes.

The intuitive PLC Control has thermostatic glue control with automatic stand-by and temperature display. The control permits the operator to engage or disable specific work operations while also providing immediate access to diagnostic messages and statistical data such as hours of operation and length of coil used. All operations can be viewed through the illuminated Plexiglas enclosure.

The EBP 950 Series is also available with pre-mill and/or corner rounding to provide even greater work flexibility (950 PM, 950 CR and 950 PMCR). The pre-mill unit option includes two opposing 60 mm diamond cutters that are micro-adjustable to mill up to 2 mm from the panel edge for optimal, chip-free glue application. The corner rounding unit is fixed to the frame crossbeam on double linear guides and features 50 mm cutter blocks as well as vertical/horizontal 50 mm diameter copiers for profiling straight, curved and beveled edges.

ETOUCH Touch Screen Control

A standard feature for the EBP 950 Series, the ETOUCH touch screen control is a 7-inch color programmable display. Operators can store up to 99 working programs, and connect to an optional network to read statistical data, diagnostic messages and online updates.

General Technical Data

| Feature | EBP 950 | EBP 950 PM |

|---|---|---|

| Feed Speed | 9 m/min | 9 m/min |

| Panel Thickness | 8 mm – 50 mm | 8 mm – 50 mm |

|

Edge Thickness in Coils or Strips |

0.4 mm – 3 mm | 0.4 mm – 3 mm |

|

Edge Thickness in Strips (Manual Feeding) |

Max 5 mm* | Max 5 mm* |

| Minimum Panel Length (Side Being Processed) | 110 mm | 110 mm |

| Minimum Panel Width | 95 mm | 95 mm |

| Flush Trimming Motors (Each) | 200 Hz - 12000 RPM - 0.37 kW | 200 Hz - 12000 RPM - 0.37 kW |

| End Trimming Motor | 200 Hz - 12000 RPM - 0.22 kW | 200 Hz - 12000 RPM - 0.22 kW |

| Compressed Air Operating Pressure | 6.5 bar | 6.5 bar |

| Compressed Air Consumption During Operation | 300 NL/min | 300 NL/min |

| Minimum Air Flow at Dust Extraction Outlets | 20 m/s | 20 m/s |

| Air Consumption of Dust Extraction System | 1550 m3/h | 1550 m3/h |

*Maximum thickness of strip is also dependent on wood hardness.

Corner Rounding Unit (950 CR, 950 PMCR)

| Feature | Specs |

|---|---|

| Motor Power | 0.22 kW |

| Tool Rotation Speed | 12000 RPM |

| Vertical/Horizontal Copier | disc Ø50 |

| Front Copier | stainless steel ring pad |

| Minimum Panel Thickness | 8 mm |

| Maximum Panel Thickness | 45 mm |

| Minimum Panel Length | 200 mm |

| Tool Radius | 2 mm |