Putsch® manufactures screens using 3 different perforation types: double bridge, wire mesh, and punched. All of them can be customized independent from any centrifugal manufacturer, and available in any dimensions.

Double Bridge

This perforation technique makes stronger screens with improved durability, while allowing sufficient flow. Our stainless steel double-bridge backing screens are fully customizable and available in any size—no matter who manufactured your centrifuge. Built tough with solid construction and thick materials, they’re made to last. The large open area and optimally placed support points (bridges) help maximize molasses drainage. We deliver them pre-bent to match your basket radius, so they’re ready to install right out of the box.

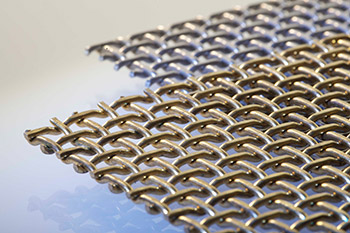

Wire Mesh

Putsch® wire mesh screens are made of interwoven stainless steel or brass wires forming a semi-flexible grid. We custom-build each screen to your specs—any size, wire diameter, or mesh configuration you need—regardless of your centrifuge brand. Alongside the classic wire mesh, we also offer a "DOVEX" version with a flat side, available in both materials. Screens can be shipped to you pre-cut to size or in convenient rolls—whatever works best for your setup.

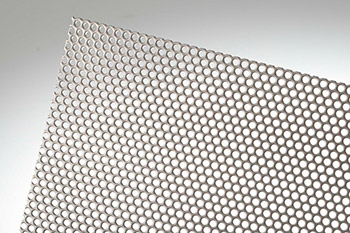

Punched

Putsch® punched backing screens are available in both stainless steel and copper, and can be customized to fit any dimensions, regardless of the centrifuge manufacturer. We offer these screens either cut to size or in roll format, depending on your needs. Thanks to our in-stock inventory, we’re able to ensure short lead times and prompt delivery.

Details

| Double Bridge | Mesh Wire | Punched | |

|---|---|---|---|

| Max. width | 52.362" (1330 mm) | 47.244" (1200 mm) | |

| Open Area | 58% | 25–83% | 23% |

| Screen Thickness | 0.236" (6.0 mm) | 0.098" (2.5 mm) | |

| Material thickness | 0.039" (1 mm) | 0.020" (0.5 mm) | |

| Mesh density | 1–500 mesh/in² (0–200 mesh/cm²) | ||

| Wire diameter | 0.001–0.118" (0.025–3 mm) |