Do you have a design, but do not have the manufacturing capability in-house? Most likely we can provide machining and fabrication services. For customers in a variety of industries, such as construction or tool and dye, who need structural parts, Putsch® can design, engineer and manufacture them upon request.

We’re not a fit for everyone; however, we usually serve companies in Asheville and Western North Carolina, as well as areas in and around Greenville, SC; Spartanburg, SC; Knoxville, TN and Charlotte, NC.

Outsourcing to Putsch® is an attractive, cost-saving move for customers that need standard or custom-designed parts for small and medium production runs and demand a quick turnaround—without sacrificing quality.

Review our manufacturing capabilities below. To discuss special design or assembly requests, please contact Engineering.

| Flow Water Jet | Capacity: 12' long x 6' wide x up to 6" plate thickness |

|---|---|

| Metal plate roller | Capacity: 6’ wide x up to 1-1/4" plate thickness |

| Horizontal metal band saw | Capacity: 16” square at 90° cutting angle |

| Sheet metal shear | Capacity: 10’ wide x up to ¼" plate thickness |

| Sheet metal press brake | Capacity: 8" wide x up to ¼" plate thickness |

| CNC lathe | Capacity: 6-1/2" diameter x 20" long |

| Conventional lathe | Capacity: up to 100" diameter |

| CNC milling centers | Capacity: 60" long x 30" wide x 20" high |

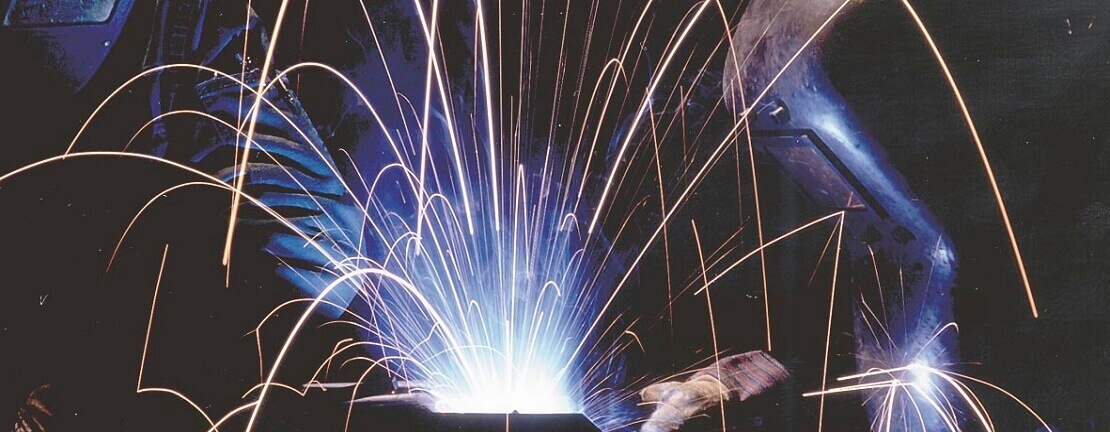

| Welding Services | ASME Boiler and Pressure Vessel Code (Section IX) |

| Stainless Steel Fabrication |