American Crystal Sugar's experiences with a Putsch® Jet Wash Roller Table

This paper reviews the operating success and problems of the Putsch® Jet Wash Roller Table elicited at the American Crystal Sugar’s plant in Minnesota. The economic justification of the spray table was that it reduced sugar loss from lower residence time. Intangible benefits included better separation of flume water from beets. Problems were identified with clarified water supply to the spray nozzles and the impact it has on beet washing. The main benefits sited in this paper from the installation of the spray table were increased beet washing effectiveness, reduced flume water carryover, and reduced sugar loss to flume.

Introduction

American Crystal Sugar Company is a farmer owned cooperative and has a total of six factories; three in Minnesota, two in North Dakota and one in Montana. Approximately 10 million tons of beets are processed each year by American Crystal Sugar Company which operates around 250 days from September through May. Long term beet storage is required for both fresh and frozen beets. The area where American Crystal Sugar operates is referred to as the Red River Valley. The five:

- East Grand Forks, Minnesota USA – 9000 tons per day

- Hillsboro, North Dakota USA – 9000 tons per day

- Drayton, North Dakota USA – 7000 tons per day

- Moorhead, Minnesota USA – 6000 tons per day

- Crookston, Minnesota USA – 6000 tons per day

Jet Wash Roller Table

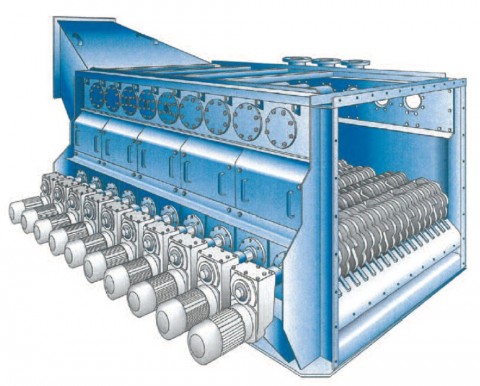

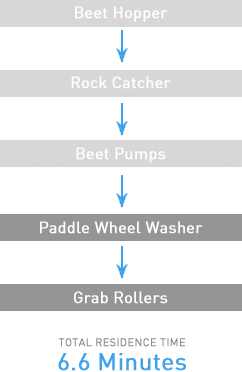

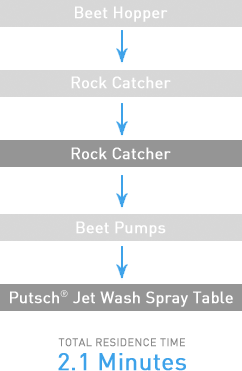

The Putsch® Jet Wash Roller Table (figure 1) is used to separate water, sand and small rocks as well as broken beet pieces from a flume stream. The flume content runs mostly over a pre-dewatering grate. The Jet Wash Roller Table consists of a steel frame on which several roller shafts are arranges on roller bearings. Rubber discs are arranged on the shafts. Before the installation of the Putsch® Jet Wash Roller Table (Putsch® JWRT) beet cleaning at American Crystal sugar involve the following: Beet hopper - Putsch® Rock Catcher - Beet Pumps – Paddle Wheel Washer - Grab Rollers. The total residence time was 6.6 minutes (figure 2). After installation of the Putsch® JWRT, the new schematic is:

Beet Hopper - Putsch® Rock Catcher - Putsch® Rock Catcher - Beet Pumps - Putsch® JWRT. The total residence time was reduced to 2.1 minutes (figure 3).

Operational Aspects

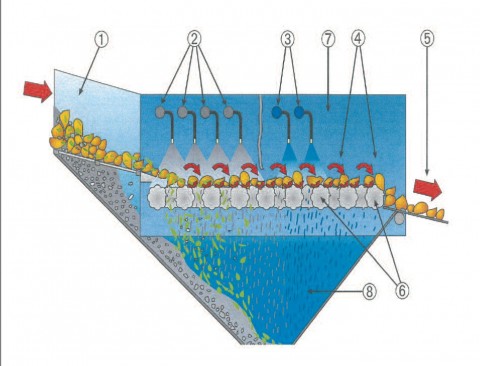

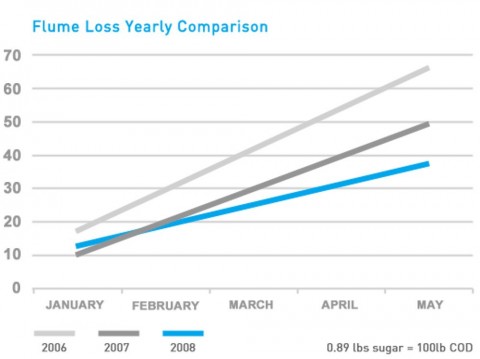

The inlet of the Putsch® JWRT (figure 4) is either a dewatering grate or a chute. It is important to have the beets enter the wash table evenly. This was achieved by having a rectangular chute that is 6” below the outlet pipe of the beet pumps. The 16’ long rectangular chute with the drop from the beet pump naturally distributes evenly as it is fed into the beet washer. The optimized design of the wash rollers causes a continuous rotation of the beets which achieves a thorough cleaning. During the first spray area, the beets are washed with flume water that removes sand, gravel, small stones and other debris. In the second spray area, the beets are sprayed with fresh water and a very substantial amount of flume water on the beets will be rinsed off. Consequently, fewer bacteria reach the extraction stage and the risk of infection is minimized. Sugar loss reduction. As a result of installing the Putsch® JWRT, we also experienced a significant reduction in sugar loss to the flume (figure 5) amounting to up to 14.9 lbs/ton beets of COD over the period of four months (1 January - 30 April). Also, once the beets travel through the Putsch® JWRT, a substantial amount of dirt is removed and the final dirt content is lower as compared to other factories in the Red River Valley. As a result, a lower raw juice solid percentage is attained which reduces the load of the juice purification. The spray table was also effective at removing flume water carryover into diffusion/process. We conducted a comparison of the Putsch® JWRT before and after installation with regard to the Lactic Acid Turndown Ratio (LATR).![]() For 2006 and 2007 the LATR was 39 and 75, respectively.

For 2006 and 2007 the LATR was 39 and 75, respectively.

Further Benefits

The installation of the Putsch® JWRT had a significant impact on reducing waste water inventory and overall factory odors. We have also experienced an improved flume water loss accounting and better water management practices. Another advantage of the Putsch® JWRT is that the washing shafts are mounted with pillow block bearings and the seals on the sides are special double lip gaskets. Each shaft is powered by a separate gear motor which allows the Putsch® JWRT to continue to operate in the event one should fail and/or if service is needed, each shaft can be exchanged relatively quickly.

Reliability

After two years of operations the seals were still in good condition and in addition, we did install an auto greasing unit. Another novel feature is the specialized rubber design of the Putsch® rollers which allows for long term usage with minimal maintenance. After two years, no appreciable wear on the rollers. The upper portion of the Putsch® JWRT has an aluminum cover which can be removed quickly in case of maintenance and repair. Jet tubes can be removed without disassembly of the connected header pipe. Also engineered on the Putsch® JWRT are ceramic spray jets attached to flexible high pressure hoses which can be exchanged individually.

Wash Water Supply

It is essential to have a good wash water supply coming into the unit. If the wash water is not filtered properly, a number of problems can occur. A high-quality wash water supply protects the nozzles from not only plugging, but also prevents wear on the ceramic portion of the nozzles. Poor wash water supply will also result in plugged headers. Overall we have been extremely pleased with the Putsch® JWRT. It has improved our operation in many areas. Excellent washing of the beets, decreased infection risk into the system, minimized our sugar loss and had a favorable environmental impact as well.