When it comes to woodworking, two of the most common tools for making precise cuts are the vertical panel saw and the table saw. Both are designed for cutting large sheets of wood, plywood, and other materials, but they each offer unique advantages depending on your specific needs and workspace. So, how do you decide between a vertical panel saw and a table saw for your next project? In this article, we will compare the two saws, discussing their strengths and weaknesses to help you make an informed decision.

What is a Vertical Panel Saw?

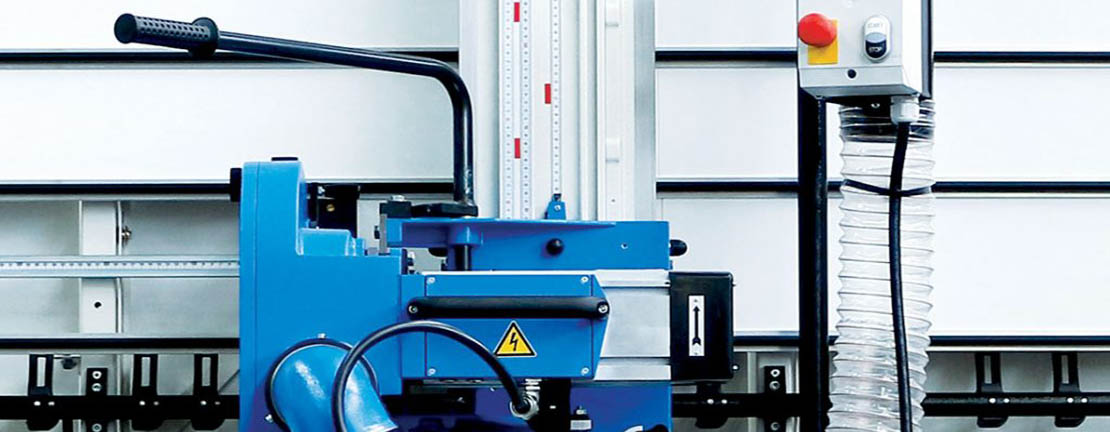

A vertical panel saw is a specialized tool designed primarily for cutting large sheets of material such as plywood, MDF, melamine, and plastic. Unlike a traditional table saw, where the material is pushed through a stationary blade, a vertical panel saw has a vertically mounted saw blade that moves along a horizontal track. The material is positioned vertically on the machine, and the saw is guided along the sheet to make the cuts.

This tool is ideal for cutting large panels with precision, and it’s especially useful in environments where space is limited, such as small workshops or professional cabinet-making shops. The vertical panel saw is designed for efficiency and safety, providing a clean cut while reducing the risk of the material shifting during operation.

What is a Table Saw?

A table saw is a versatile cutting tool that features a horizontally mounted circular blade, with the material being fed into the blade by the operator. It is a staple in most woodworking shops due to its versatility, accuracy, and ability to make a wide variety of cuts, including crosscuts, rip cuts, and bevel cuts.

The table saw is generally larger and heavier than a vertical panel saw, making it more suitable for shops with enough floor space to accommodate the saw. It can handle a range of materials, from thin plywood to thick hardwood, and offers several features that allow for customizable cuts, including adjustable fences, blade height, and tilt.

Comparing the Vertical Panel Saw and Table Saw

1. Space Efficiency

One of the most notable differences between the two tools is the amount of space they require. A vertical panel saw is designed to take up less floor space while still allowing you to cut large sheets of material. It’s often mounted on a wall or frame, saving valuable shop floor space. The vertical cutting motion allows you to stand upright while operating the saw, reducing physical strain and providing better ergonomics for long hours of work.

On the other hand, a table saw requires a large, flat surface and can take up more space in your workshop. It’s typically positioned on the floor, and its size and shape can make it difficult to move or store. While the table saw is versatile, its larger footprint can be an issue for those with limited workshop space.

2. Precision and Accuracy

Both saws can provide excellent precision, but they are suited for different cutting tasks. A vertical panel saw is specifically designed for straight cuts on large panels. Its track-based system ensures the saw blade remains aligned and stable, which leads to accurate and straight cuts every time. This makes it ideal for projects that involve cutting large sheets of material, such as cabinetry, shelving, or wall paneling.

A table saw, while versatile, requires a bit more effort to achieve the same level of precision for cutting large sheets. The material is fed through the blade by hand or with the aid of a fence, which requires constant attention to maintain accuracy. A table saw is better suited for smaller, more detailed cuts and tasks such as crosscutting, rip cutting, and angled cuts.

3. Cutting Capacity

When it comes to cutting large sheets of material, the vertical panel saw has a clear advantage. It can handle full-sized panels (typically 4’x8’) with ease, making it ideal for cutting plywood, MDF, or melamine. The vertical position of the material allows for better control and support during the cutting process, reducing the chance of material shifting or causing an uneven cut.

The table saw, while capable of cutting large sheets, requires more space and sometimes additional supports or rollers to manage large panels. Handling heavy or large materials can be more challenging, as the operator must manually push the material through the blade. The table saw is better suited for smaller workpieces, but with the right jigs and extensions, it can handle larger cuts as well.

4. Safety

Safety is always a top priority in woodworking. Both the vertical panel saw and table saw have safety features, but they operate differently in terms of risk management.

A vertical panel saw is generally considered safer when working with large sheets of material. The vertical design keeps the operator's hands away from the blade, and the material is securely positioned and supported during the cutting process. The saw’s motion is also more controlled, reducing the risk of accidents.

In contrast, a table saw has a higher risk of kickback, especially when working with larger sheets of material. Operators must be cautious when feeding the material through the blade, as improper handling can lead to injury. Many modern table saws include safety features like blade guards, anti-kickback pawls, and riving knives, but they still require more attention and caution than a vertical panel saw.

5. Portability

While both tools can be moved, the vertical panel saw is generally easier to relocate, especially if it’s mounted on a wall or equipped with wheels. Its compact design makes it easier to transport between job sites or move within a small workshop. It’s ideal for mobile woodworkers or professionals who need a saw that can fit into tight spaces.

The table saw, being larger and heavier, is less portable. Some models come with wheels for easier movement, but transporting them can still be cumbersome. For those who need a saw that can handle larger projects on the go, the vertical panel saw offers better portability.

Which is Better: Vertical Panel Saw or Table Saw?

Choosing between a vertical panel saw and a table saw ultimately depends on your specific needs, workspace, and the type of work you do.

If you primarily work with large sheets of material and need precision cuts, a vertical panel saw is likely the better option. It’s more space-efficient, safer, and designed for large-scale cutting.

If you need a more versatile tool for a variety of cuts, including crosscuts, rip cuts, and bevels, and you have the space to accommodate it, a table saw is a great investment. It’s perfect for smaller, detailed work and can handle a wide range of materials.

For woodworkers who deal with large panels on a regular basis, the vertical panel saw is often the preferred choice due to its ease of use, accuracy, and space-saving design. However, for those who need a general-purpose saw that can handle both small and large cuts, a table saw remains a staple in many workshops.

Conclusion

Both the vertical panel saw and table saw have their place in a woodworking shop. The decision comes down to the nature of your work, the space available, and your specific cutting needs. By understanding the strengths and weaknesses of each tool, you can choose the one that best suits your projects and improves your workflow. Whether you choose the space-saving convenience of the vertical panel saw or the versatility of the table saw, both will provide high-quality cuts for your woodworking tasks.