When it comes to creating visually striking and functional designs in woodworking, V-groove paneling is an incredibly popular choice. Whether you're a professional carpenter, a DIY enthusiast, or someone looking to add a sophisticated touch to your home decor, V-groove paneling offers a sleek and stylish look that’s versatile enough to suit any project. But to achieve precise and clean cuts, you’ll need the right tools, particularly saws designed for cutting V-grooves.

In this guide, we'll explore everything you need to know about V-groove paneling, the best saws to use for cutting V-grooves, and why V-grooves are such an appealing option for interior design and woodworking projects.

What is V-Groove Paneling?

V-groove paneling refers to a type of decorative paneling where grooves are cut into the surface in the shape of a "V." These grooves create a distinctive, patterned look that adds texture and visual interest to walls, ceilings, cabinetry, or furniture. V-grooves are particularly effective in creating a modern, yet timeless appeal, often resembling beadboard or shiplap designs, but with a more angular, contemporary edge.

The paneling itself is typically made from wood, MDF, or plywood, and the grooves can be shallow or deep, depending on the desired effect. The V-groove effect can also make it easier to install, as the grooves help align the panels and provide natural seams where they fit together.

Why Choose V-Groove Paneling?

- Aesthetic Appeal: V-groove paneling adds texture and depth to any space, making it ideal for feature walls, wainscoting, and other decorative elements.

- Ease of Installation: The groove pattern not only adds to the aesthetic but also helps with installation by aligning panels neatly and securely.

- Versatility: Suitable for a wide range of applications, including walls, ceilings, cabinet doors, and furniture. V-grooves can be customized to create both traditional and modern looks.

- Durability: V-groove paneling is often made from durable materials like MDF or solid wood, providing a long-lasting and sturdy finish.

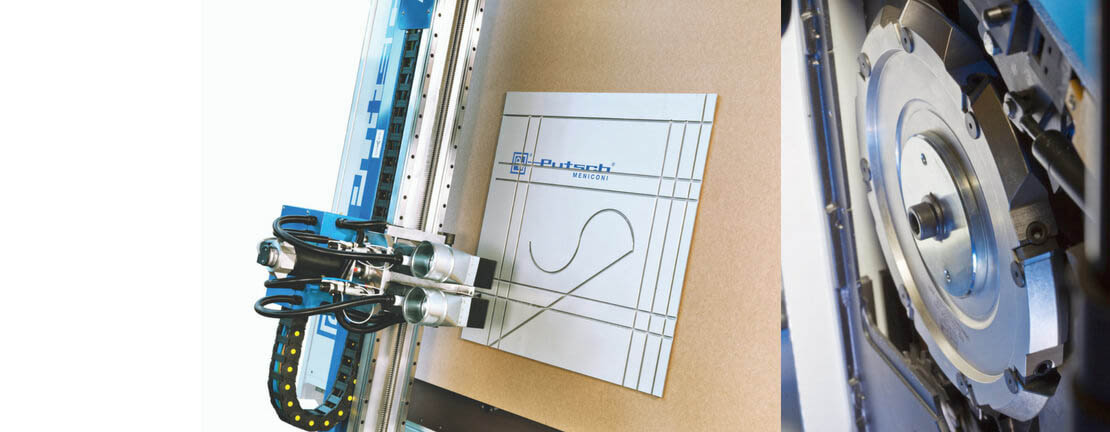

What Saw Should You Use to Cut V-Grooves?

To create V-grooves in paneling, you’ll need a specialized tool capable of making precise, clean cuts. Several types of saws can be used for this purpose, but not all saws are designed to cut V-grooves efficiently. Let’s take a closer look at the best saws for the job.

1. Table Saws with a V-Groove Blade

A table saw with a V-groove blade is one of the best tools for cutting grooves into paneling. Table saws are designed for straight cuts, but with the right blade, they can easily handle the precision required for cutting grooves.

- Blade Choice: To cut V-grooves, you'll need a special V-groove blade. These blades are typically carbide-tipped and designed with the specific geometry needed to create the "V" shape in the wood.

- Adjustability: Table saws offer excellent control over cutting depth and groove width, making them ideal for precise, customized V-groove paneling.

- Accuracy: A table saw provides consistent, straight cuts, ensuring that your grooves are uniform and perfectly aligned across the paneling.

2. Router with a V-Groove Bit

For finer, more detailed V-grooves, a router fitted with a V-groove bit is another excellent choice. Routers allow for highly accurate groove cuts and can handle different depths and widths depending on your needs.

- Flexibility: Routers allow for greater flexibility when it comes to creating grooves of varying sizes and depths.

- Customization: By adjusting the router's depth setting, you can achieve different groove effects and customize the finish to suit your project.

- Precision: A V-groove bit for the router creates cleaner, more defined edges compared to traditional saw blades, making it ideal for detailed work.

3. Circular Saws with a V-Groove Blade

If you’re working with large panels or need a more portable solution, a circular saw equipped with a V-groove blade is another viable option. Circular saws are versatile and portable, but they require a steady hand to ensure clean, straight cuts.

- Portability: If you need to cut large panels or work in various locations, a circular saw offers portability that table saws and routers cannot match.

- Precise Cuts: While circular saws can cut V-grooves effectively, they may not offer the same level of precision as a table saw or router. However, with proper guides and setup, you can still achieve excellent results.

4. Miter Saws for Grooves on Short Panels

For shorter pieces of paneling, a miter saw can be used to make V-grooves. Although miter saws are typically used for crosscuts and angle cuts, when paired with a V-groove blade, they can help you cut grooves in shorter panels with precision.

- Accuracy: Miter saws are ideal for cutting precise, clean grooves on shorter panels.

- Speed: Miter saws are fast, making them a great choice when you have several panels to cut, especially for projects like wainscoting or feature walls.

Tips for Cutting V-Grooves in Paneling

- Measure Twice, Cut Once: Always double-check your measurements before cutting. Make sure your grooves are aligned and spaced evenly across the panel.

- Set the Correct Depth: Adjust the cutting depth to achieve the desired groove effect. A shallow cut gives a subtle look, while a deeper groove creates more pronounced lines.

- Use a Guide: For straight, consistent cuts, use a fence or guide rail, especially if you’re using a circular saw or router.

- Test Cuts First: Practice on a scrap piece of wood to ensure the groove depth and width are perfect before cutting on your actual paneling.

Conclusion

V-groove paneling is a versatile and visually appealing choice for a wide range of woodworking and home improvement projects. Whether you’re designing feature walls, cabinetry, or custom furniture, cutting precise V-grooves is crucial to achieving the best results. By using the right saws—whether a table saw, router, or circular saw—you can ensure that your grooves are clean, accurate, and perfectly aligned.

For those looking to create high-quality V-groove paneling, investing in the right tools and taking the time to set up your cuts correctly is essential. With the right saw and technique, you’ll be able to create professional-looking paneling that adds both beauty and functionality to your space.